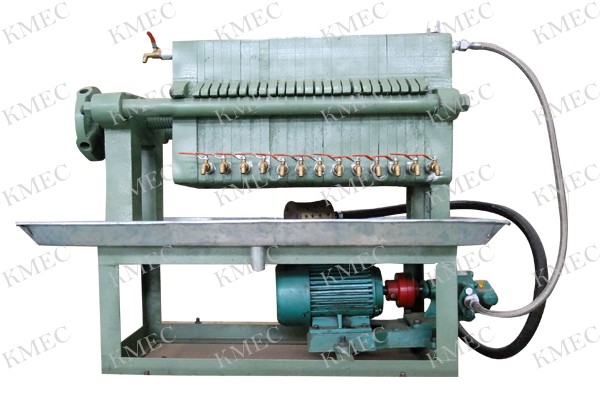

6LB Series Oil Filter Press

The 6LB series oil filter press is plate type oil filter machine which is mainly being used for separating solids and liquids in the oil production plants for edible or vegetable oils. This model plate filter press is suitable for filter crude oil and refined oil, and it is also could be applied to filter bleaching oil in the oil refining plants.The plate oil filter press we produced is qualified the technology requirements of the IB/T 4333-1997 the pressure oil-filter in compartmental and plate type. KMEC supplies a wide range of filter press machines designed to give maximum filtration efficiency, longer service life and less maintenance. The filter presses are available in different sizes and various capacities. We can also provide oil filter presses to custom specifications.

Technical Data

| Model | No.of filter plates | Dimension of filter plate | Working pressure | Productivity | Power | Dimension | Weight |

|---|---|---|---|---|---|---|---|

|

6LB-250

|

13pcs

|

250*250mm

|

0.3-0.4MPa

|

100kg/h

|

0.75kw

|

780*530*670mm

|

155kg

|

|

6LB-350

|

25pcs

|

350*350mm

|

0.3-0.4MPa

|

200kg/h

|

1.1kw

|

1300*750*700mm

|

470kg

|

Oil Filter Press Filtering Cloth

The oil filter press utilizes a fine-mesh filtering cloth, which is particularly useful in bio-diesel oil refinement. The filtrating cloth between the filter plates forms many rooms. The oil under the pressure goes through the filtrating cloth, gets out from the faucet beneath the filtrating cloth. The oil, under pressure, is forced through the filtrating cloth and exits from the faucet below.Matters Need Attention When Using an Oil Filter Press

- All the pipe clips should be tightened to prevent leakage of the oil.

- Filtering cloth should be put between the filter plates, then lightened by tension bolt to make sure no leakage exists.

- Oil will be expelled 2 or 3 minutes after starting the machine under normal operation, If no oil exits the oil press, please stop the machine or inspect oil pipe for blockage.

- he valve is mounted for use when the filtering cloth becomes torn or the oil looks becomes dirty.

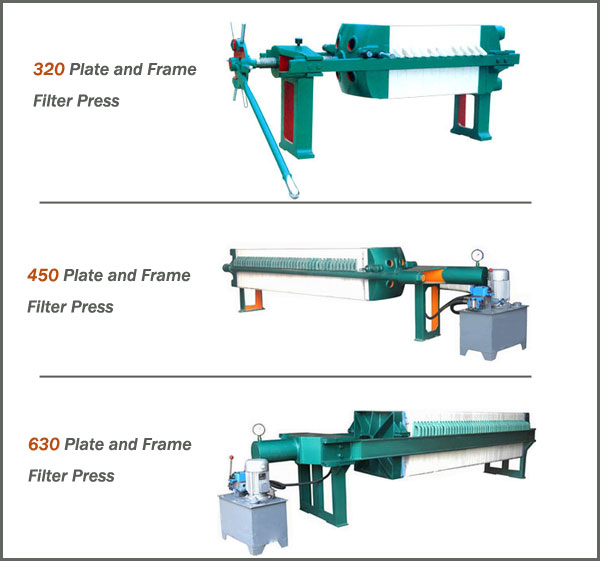

BAM Series Plate and Frame Filter Press

The filter series of our company accord with the national and related industrial regulations (see in technical parameters) and also be produced according to the customers’ special needs. Our products are qualified and have passed the ISO9002 registration.

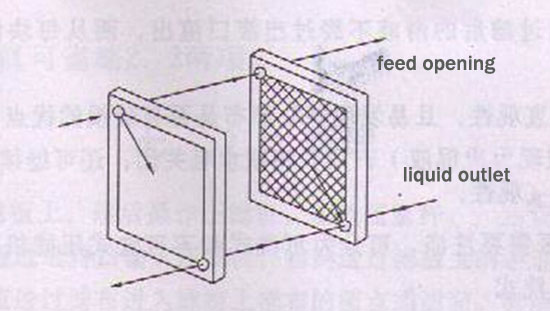

Structure of Frame Oil Filter

The Plate and frame filter press is a basic filtering unit that consisit by filter frame and filter plate. The filter is formed by four parts:Mainframe, filtering parts, press and control. The filter part is constituted by several filter boards and frames which are ranked in the main beam in an order—the filter is between filter board and fram.

Working Principle

When material come into filter room from hole in push plate, the solid bigger than the hole of filter intermediary is hold in the filter room and become solid lump while the liquid flow out from the discharge hole by free flow and undercurrent flow. Under each filter board there is a hole with a water nozzle that the water flow out from the nozzle is called free flow, while the way brings water from each filter boars together and flow out by discharge channel is called undercurrent flow.Technical Data

| Model | Filtering Area(㎡) | Dimension inside the frame(mm) | Filter cake thickness(mm) | Number of filter plate(piece) | Number of filter frame(piece) | Capacity of the filtering chamber(L) |

|---|---|---|---|---|---|---|

| BAMS1/320-30U | 1 | 320*320 | 30 | 4 | 5 | 15 |

| BAMS2/320-30U | 2 | 9 | 10 | 31 | ||

| BAMS3/320-30U | 3 | 14 | 15 | 46 | ||

| BAMS4/450-30U | 4 | 450*450 | 30 | 9 | 10 | 61 |

| BAMS6/450-30U | 6 | 14 | 15 | 91 | ||

| BAMS8/450-30U | 8 | 19 | 20 | 122 | ||

| BAMS12/450-30U | 12 | 29 | 30 | 182 | ||

| BAMS16/450-30U | 16 | 39 | 40 | 243 | ||

| BAMJ20/630-30U | 20 | 630*630 | 30 | 24 | 25 | 298 |

| BAMJ30/630-30U | 30 | 37 | 38 | 453 | ||

| BAMJ40/630-30U | 40 | 49 | 50 | 595 |

| Model | Rated filtering pressure(Mpa) | Max displacement of the compression plate(mm) | Overall dimension(mm) | Overall weight(mm) | Foundation dimension(mm) |

|---|---|---|---|---|---|

| BAMS1/320-30U | 1.0 | 300 | 1210*660*650 | 350 | 710*150*500 |

| BAMS2/320-30U | 1565*660*650 | 400 | 1020*150*500 | ||

| BAMS3/320-30U | 1875*660*650 | 455 | 1330*150*500 | ||

| BAMS4/450-30U | 0.6 | 400 | 1940*870*870 | 720 | 1160*180*600 |

| BAMS6/450-30U | 2250*870*870 | 800 | 1470*180*600 | ||

| BAMS8/450-30U | 2560*870*870 | 880 | 1780*180*600 | ||

| BAMS12/450-30U | 3160*870*870 | 1020 | 2380*180*600 | ||

| BAMS16/450-30U | 3770*870*870 | 1180 | 2990*180*600 | ||

| BAMJ20/630-30U | 0.6 | 500 | 3400*1150*1160 | 1980 | 2490*400*800 |

| BAMJ30/630-30U | 4220*1150*1160 | 2350 | 3310*400*800 | ||

| BAMJ40/630-30U | 4950*1150*1160 | 2680 | 4040*400*800 |

Oil Filtering Plates

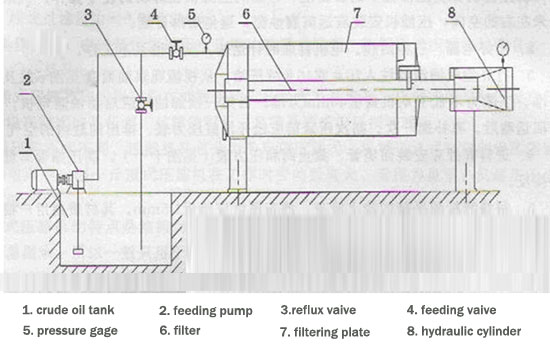

Filter Press Operation

- Tighten the filtering plate;

- Open valve 4, close valve3;

- Start feeding pump2 to make the crude oil go into the filter.;

- Observe the pressure of pressure gage during filtering, adjust the filtering pressure according to practical situation, open the valve 3 to make the pressure bellow 0.6Mpa;

- Adjust the feeding pressure with valve 3, close the feeding pump when the quantity of filtered oil become less, if it’s necessary to wash the plate, open the filtering plate and discharge filter cake

- If the filter cake isn’t dry enough after opening the filter plate, close the filtering plate and keep on doing the filtering process.

Feel free to get in touch with us any time you are interested in our filter press!